In a previous article, we looked at how to select reliable Chinese foundries and avoid production and compliance risks from the perspective of an overseas brand. Today, we’re reversing that perspective: from the standpoint of a Chinese manufacturer, we’re going to talk about how to move from “alternative supplier” to “trusted long-term partner” in international collaborations – and beyond. -and even go further, building their own brands and establishing overseas markets.

Opportunities Have Their Thresholds

To realize the transformation from “OEM factory” to “international partner”, it is not enough to rely on product strength alone. Many Chinese factories, when expanding their business overseas, often fall into some seemingly reasonable but restrictive thinking patterns, such as: the lower the offer, the more attractive to the customer, the brand is only concerned about the price, and as long as the shipment is on time, it is a good cooperation. Behind these inertia thinking lies a cognitive bias towards the deeper expectations of international customers for long-term cooperation, safety compliance and efficient communication.

Different from the early years of a large number of low-requirement orders, today’s brands pay more attention to the fine sampling, continuous supply capacity and the transparency of the collaboration process. This means that even if the product quality is qualified, if the communication efficiency, contract execution or quality control mechanism is not up to standard, the order may still be lost. The new round of competition standards, has shifted from pure cost advantage to a comprehensive test of “overall delivery capacity”.

What Do Overseas Brands Really Care About?

Because the focus of overseas brands has long since shifted from “can we do it” to “is it worth trusting”, factories must accurately understand the client’s evaluation criteria before entering into cooperation. In our practical legal services, we have come into contact with a large number of cases of collaboration between domestic and foreign companies. From the point of view of overseas brands, they generally pay attention to the following points when they screen cooperative factories:

- Supply Chain Stability: This is not just about being able to deliver on time, but also about the maturity of the enterprise’s management and its ability to withstand the impact of variables such as international logistics/price hikes of raw materials/export policies.

- Quality control and certification system: whether the products produced meet the rigid requirements of the exporting country, it is difficult for factories that lack a system to gain favor.

- Contract and intellectual property protection: Brands worry about design theft, mold misuse, and unauthorized exports. The willingness to sign clear cooperation agreements is a sign of their trust.

- Communication and Response Mechanism: The ability to respond to timelines, changes, and compliance is also a key focus for overseas clients to examine.

These are the same points we emphasized in our previous article, “An Australian Brand Went from “Wanting to Make Products” to OEM in China, and They Did These Four Things Right”.

How Can Factories Avoid Common Cognitive Biases?

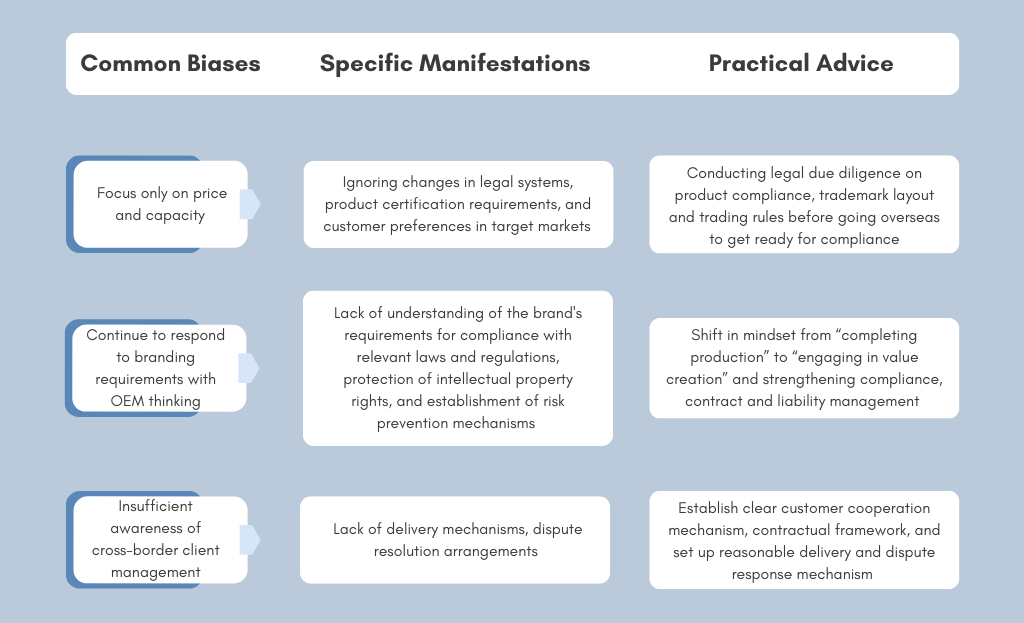

Although more and more Chinese manufacturing enterprises wish to “go overseas”, they often encounter some biases in their thinking that may affect their cooperation opportunities before they can establish stable cooperative relationships with overseas clients. Combined with our firm’s experience in serving clients, we have summarized the following typical cognitive biases and corresponding suggestions.

The first bias is to focus excessively on price and capacity, while ignoring compliance, liability and brand preferences of the target market. Many OEMs believe that as long as product quality is reliable and costs are low enough, it is enough to attract customers. But in fact, overseas brands are paying more and more attention to product compliance, consumer protection, environmental protection and business responsibility. If you do not understand the rules and requirements of your target market, you may be turned away before you enter. We recommend that companies conduct systematic compliance due diligence before entering into a partnership, especially the assessment of key areas such as product regulations, applicable contract law and intellectual property regimes.

The second bias is that the traditional “OEM” mentality is still used to respond to the requirements of brand cooperation, and there is a lack of understanding of the changes in the mode of cooperation. In modern supply chain management, brands increasingly expect OEMs to take on more responsibilities, such as complying with relevant laws and regulations, protecting intellectual property rights, and establishing risk prevention mechanisms. If they remain in the “production only” mode, they will not only be unable to meet customer requirements, but will also be in an unfavorable position in disputes. We recommend that enterprises adjust their role and emphasize contractual structure, intellectual property rights and commercial liability arrangements, and gradually transform from “producers” to “partners”.

The third bias is the failure to adapt to the expectations of overseas customers for communication efficiency, delivery standardization and risk prevention. Some OEM factories lacked clear cooperation mechanisms, division of responsibilities and dispute resolution arrangements during the initial negotiations, which led to a trust crisis in subsequent cooperation. It is recommended that enterprises prepare a set of standardized cooperation framework in advance before contacting customers, including contract terms, delivery plans and dispute resolution paths, etc., to demonstrate to the partners that they have the awareness and attitude of international cooperation.

This image is an original creation by the author based on relevant data and materials. The copyright belongs to Sunfield Chambers Solicitors & Associates. Unauthorized reproduction, modification, or commercial use in any form is prohibited. For reprinting, please cite the source and contact marketing@schambers.com.au for permission.

Summary

In the process of China’s manufacturing towards high quality, compliance and globalization, the real gap is not productivity, but institutional strength and trust. Whether or not we can win the sustained cooperation of overseas brands depends on whether or not factories have a set of “brand awareness + legal awareness” underlying capabilities.

Our team has long assisted manufacturing companies in dealing with contract review, intellectual property protection, compliance counseling and other issues in the process of overseas cooperation.

Welcome to read our previous article “An Australian Brand Went from “Wanting to Make Products” to OEM in China, and They Did These Four Things Right”, to understand the key nodes from the brand’s point of view.

If you are also expanding into the overseas market, please feel free to communicate with us.

Written by Xueying Yang; Content planning: Sun Gang; Xueying Yang; Proofreading: Sun Gang

The content of this article is based on publicly available information and the author’s understanding, and does not constitute any form of professional legal advice or basis for business decisions. Readers should refer to this article in the context of their own actual situation and consult relevant professionals for specific guidance. The author and the publishing platform do not assume legal responsibility for any consequences arising from the use of the information in this article.

Consultation with Specialized Lawyers

Abraham Sun

Principal Solicitor

As the Principal Solicitor, Abraham has been working with numerous clients including listed companies, state-owned enterprises, ultra-high-net-worth clients, and investment banks. Customers in various industries including Australian and Chinese companies and individual investors, had achieved considerable economic benefits with his professional legal advice.

Annette Leung

Partner, Solicitor, Notary Public

Annette is an experienced lawyer who works with clients in a wide range of commercial and civil disputes, with a particular focus on marriage and family affairs. Also, her experience extends to assisting clients in other common law countries.

Amy Zhu

Partner, Senior Licensed Conveyancer

Amy is an experienced licensed conveyancer with years of experience in conveyancing matters. She has outstanding work experience and achievements in conveyancing services under property law and conveyancing law provisions. She is skilled in working with clients in Mandarin and English.

Ming Zhao

Partner, Solicitor

Ming is proficient in immigration law and has over 20 years of experience in this area of law. He specialises in business skills migration, employer nomination scheme, employer nomination migration in regional areas, etc. Also, Ming is highly experienced in all areas of criminal defence, including matters involving drink driving, drive while disqualified/suspended, etc.

Latest Posts:

- Privacy Challenges in the AI Era: Is Your Information Truly Secure?

- 5% Deposit Scheme Explained: New Opportunities for First Home Buyers

- Zong Fuli Steps Down: The Succession Challenge for Private Enterprises

- “I want a divorce, but he’s in prison overseas” – Wang Nuannuan’s cross-border divorce dilemma

- What is International Public Notary? A Practical Guide for Seamless Cross-Border Document Circulation

- Experiencing Domestic Violence or Harassment? Criminal Lawyers Show You How to Effectively Use AVO to Respond